PPS | Production Planning System

Efficient production as the basis for your success

A key factor behind business success is ensuring efficient production planning and control, which will allow your high product quality to stand out from the rest, despite high cost pressure and intensifying competition. For order-related production in particular, as well as long-term planning, the ability to react flexibly in a short amount of time is also important. C3 supports you in deploying and exploiting your resources optimally as well as minimizing processing times.

Your key advantages at a glance

- The combination of schedule planning and control room helps all parties produce corresponding orders, which will save on costs of set-up times and procure additional capacities

- With automatically calculated time slots for each job step, find out early which orders are behind schedule and require attention

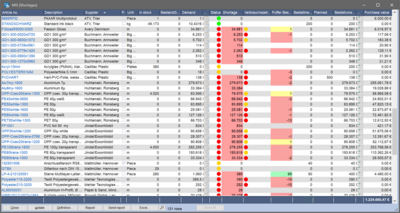

- The material-requirement analysis determines what has to be ordered at all levels of an order (material, colors, tools, etc. ) and sets up your expenditure accordingly

- Precise description of job steps and screening criteria help ensure that no QS-relevant information is lost, allowing you relax until the next QS audit

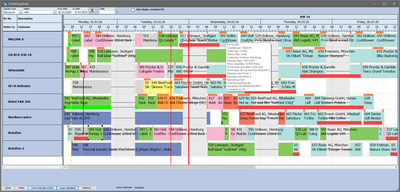

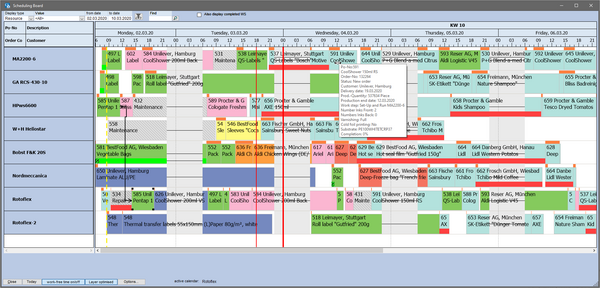

C3's graphical scheduling board provides you with optimum support for your production planning and control. In conjunction with automatic capacity planning, rough planning can be carried out automatically, e.g. based on specified delivery dates. In detailed production planning, you can then schedule specific orders precisely and react at short notice.

New or existing orders and work steps can be easily dragged and dropped onto the desired date. A variety of filters and views help you to find the optimal production sequence to continuously improve processing times and adherence to schedules. Employees at the machine workstations then receive their daily or weekly schedule either as a printed list or, for maximum flexibility, can view it online directly on the screen. The current processing status can be seen at a glance, so that production delays or machine downtimes can be identified immediately, even from the office.

Smaller orders, shorter delivery times, wider material diversity: production planning is getting more complex and faster which demands for specific knowledge of an experienced planner. This ends now: From now on C3 optimizes the whole production planning automatically with Artificial Intelligence.

C3 AI combines various novel theoretical methods from research and science to create different scenarios for example minimization of transgression of delivery dates or the maximization of (machine) capacity utlizitation.

The results are automatically created, optimized machine occupancy plans that include delivery dates, material availability and replenishment time, set-up time saving and existing capacities. New orders can be added dynamically. Flexible machine configuration allows the optimization of all set-up time relevant factors. That means: in the future your machines only get the absolute necessary modifications. With flexible emphasis you fit your focus to the current market situation. For example to emphasize delivery date fulfillment or orders from key accounts or minimization of costs.

The enormous computing power needed for this Artificial Intelligence application is offered by us, theurer.com, in high performance data centers via cloud.

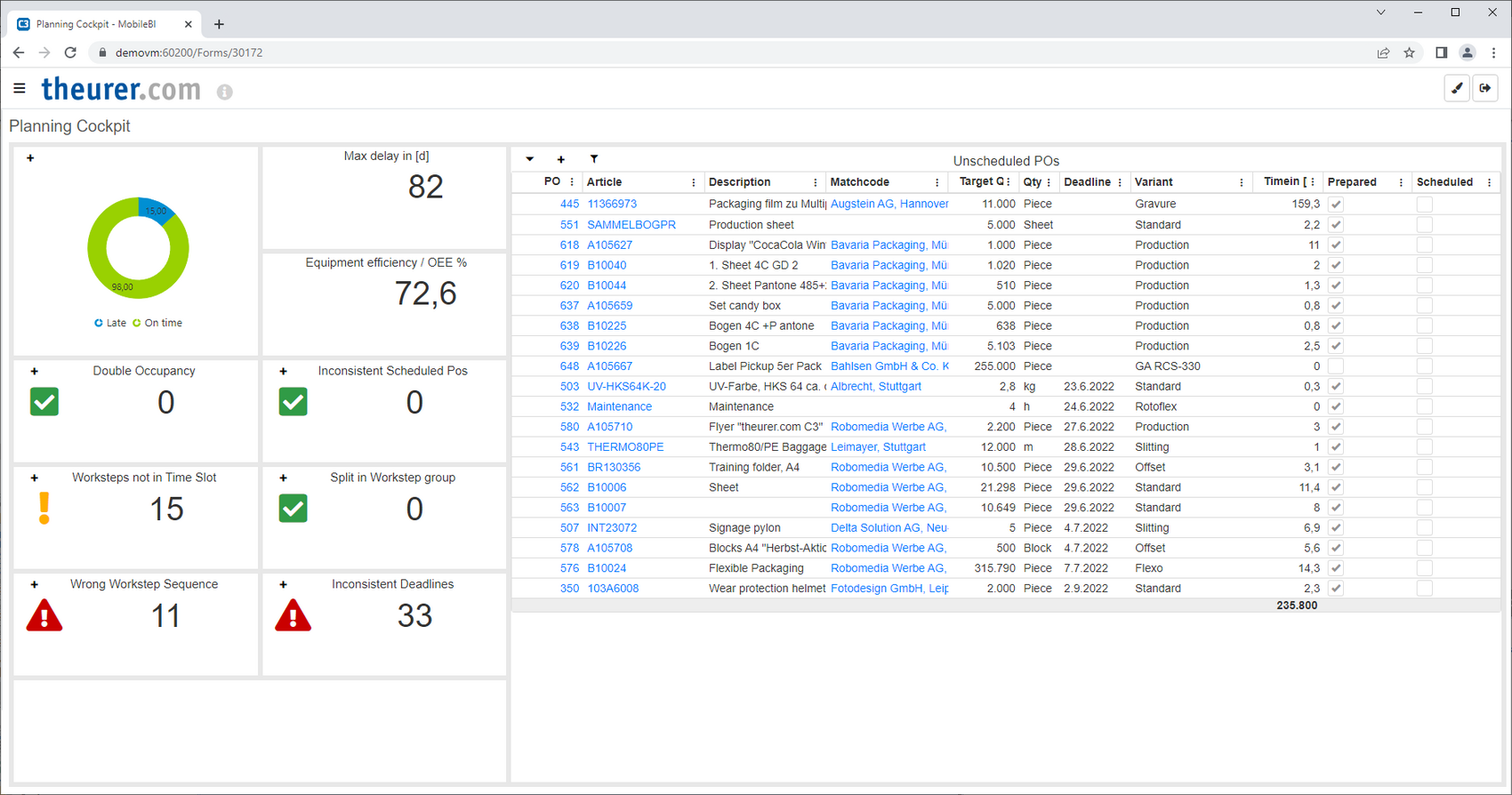

The Production Planning Cockpit provides production planners all relevant information on daily business in production planning:

- New incoming production orders are directly visible and can thus be easily scheduled

- Warnings or errors affecting ongoing production are detected and displayed so that immediate action can be taken

- Key figures in planning, such as number of orders not on schedule, total delays or overall equipment effectiveness (OEE) can be seen at a glance

The quality of the planning is thus immediately in view. The three C3 components Scheduling Board, Production Planning Cockpit and Scheduling Planning form the perfect symbiosis for your production planning.

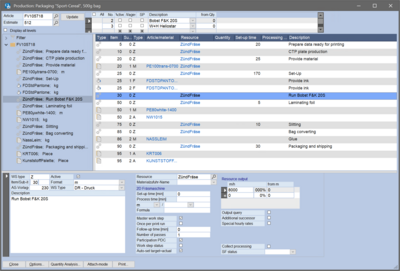

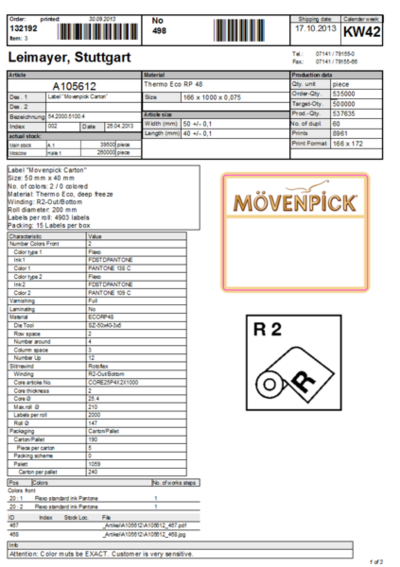

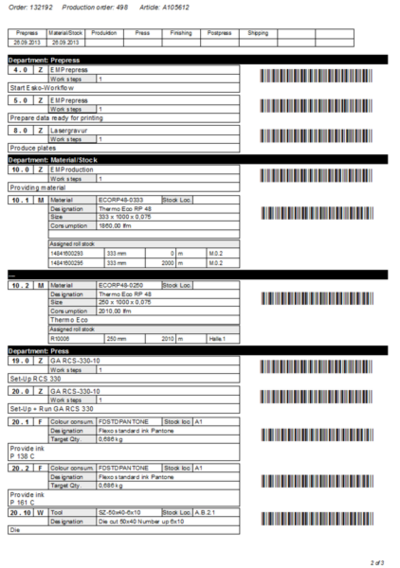

All manufacturing relevant data or manufacturing versions of an article are centrally administered in working plans. A working plan consists of individual work steps and a list of materials. Target time and material consumption details build the basis of an estimate and necessary materials and provide a calculation of the earliest possible delivery date.

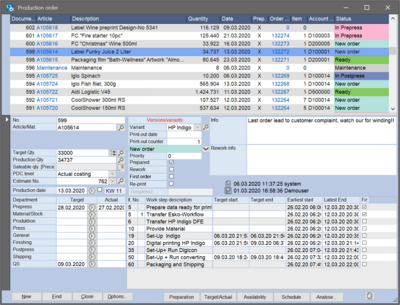

Overview of current production orders

The production order includes all information and data which are relevant for in-time manufacturing and quality assurance. Here you can find the target values such as which material should be taken in which quantity from which inventory location. The manufacturing is monittored comprehensively during its progress. Deadlines for each department can be entered and controlled. The actual data concerning the status and progress of an order comes from the data collection at the shop floor. The user therefore is always up to date on the status and progress of a certain order. Meeting delivery deadlines or providing useful information about order progress is made simple.

A special aspect is the assurance of product quality. With detailed production orders combined with the shop floor control system, quality problems can be determined in time and can be solved. Details for each work step in a production order inform your employees of particular technical features and requirements to make sure that problems that have already occurred will not happen again.

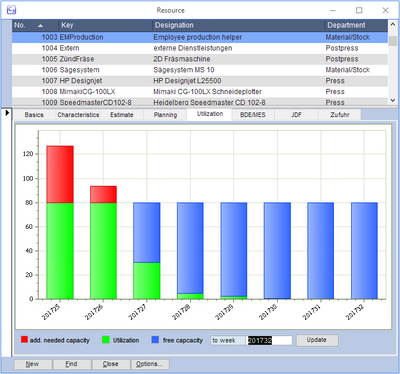

The C3 capacity planning supports the coordination deadlines, production orders and shift plans with each other. C3 automatically calculated earliest start dates and latest completion dates for every involved department or for individual work steps. As a result a detailed capacity forecast is possible and adjustable for delivery times or shift plans in time.

C3 assists you optimally in the material requirement planning. For an article or a production order, each material or article consumption is calculated. The use of bills of materials on different levels can be allocated based on article. Depending on the current inventory and the reordering time of articles or materials, purchase orders can be generated automatically or manually.

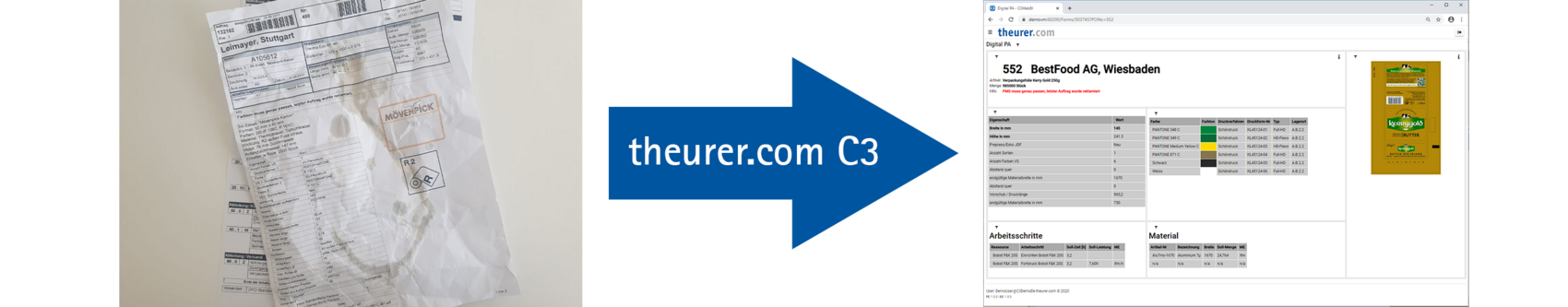

Before Working with printed production orders has always been difficult: it gets lost, destroyed or dirty beyond recognition. Either way the neede effort to work with printed orders is high and time-consuming. | After The digital production order takes you to a new level: instead of carrying a printed order around in your order bag, the digital production order is always up-to-date and shows, e.g. the QA instruction you just entered. You can call it up at any time from anywhere in the company, it cannot be lost or soiled and the paper saved by not printing protects the environment. A WIN – WIN – WIN situation! |