EST | Estimating

Industry-specific, fast and transparent

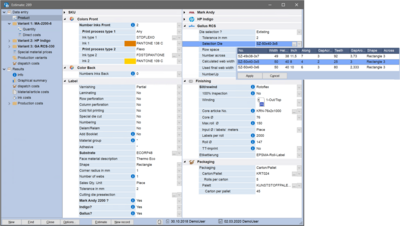

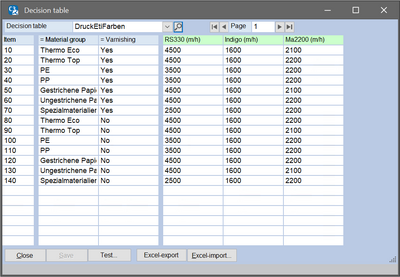

In practice, the preliminary costing must be swift and simple in foremost, while still accurate and traceable. In the area of calculation, C3 offers virtually unlimited flexibility and multiple automation options. Thanks to the individually configurable set of logic rules and self-definable templates, you can create a high-performance expert system, which means even complex calculations can be performed efficiently and transparently. Depending on your internal costing approach, you can use full, partial and/or direct costing invoices to maximize cost transparency and determine actual prime costs or minimum prices. All internal calculations are documented allowing you to trace each costing calculation step by step, while a wide range of adjustable parameters let you create diverse calculations for different product types. You can define your own formulas or decision tables for machines, which can then be used to calculate the machine performance – e.g. depending on the sheet size, material and coloring.

Your key advantages at a glance

- The product configurator lets you ensure that only coherent products are offered

- You can use your own rules and freely configurable logic for each product class to create your company-specific expert system and ensure that regardless of the processor, the same price will be issued for the same enquiry in each case

- C3 not only selects the best machine but also calculates the complete production sequence and thus determines the optimal production version for each print run

Simultaneous estimate of different productions variants including all details

With support of the shop floor control system [SFC] estimated costs and actual cost can be easily compared automatically for all production orders. Due to this automated comparison, differences between estimated and actual costs can already be seen during the production process.

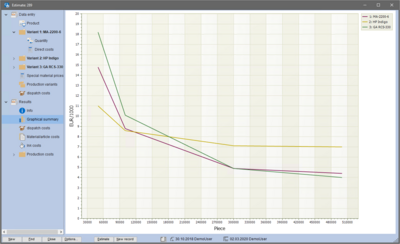

Graphical representation of the unit cost

The built-in production-versions calculation allows multiple production versions, e.g. for different criteria, to be calculated and compared at the same time. Here, C3 simulates complete production e.g. in a digital roll and conventional sheet production to determine the optimal production method for each required quantity.

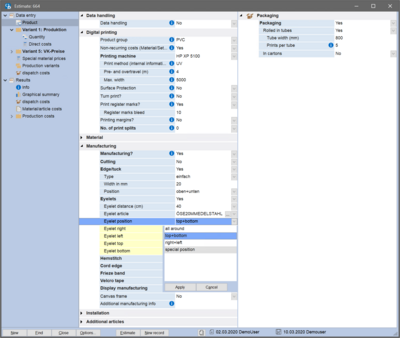

Every estimate becomes even simpler and faster with the fully integrated product configurator. Moreover, costs can no longer be "overlooked”. All relevant data for estimating a certain product is verified by C3. In the background, C3 turns this into the complete working plan and calculates the estimate according to your company specific rules. Moreover, all required data for a later actual cost comparison is already calculated. You can set rules and restriction conditions for certain characteristics of the product class for every product. As an example, the following rule could be defined: "If a product form 'rectangle' is selected, the user is then asked to enter a corner radius." Moreover, certain product characteristics can cause additional working steps, an additional material consumption or check the technical feasibility according to your specific rules. A rule could be defined for example: "If the backside is printed, an additional working step 'Make ready turn bar’ is inserted automatically." Your own rules are customized, but not programmed, so they don’t need to be changed for a software update.

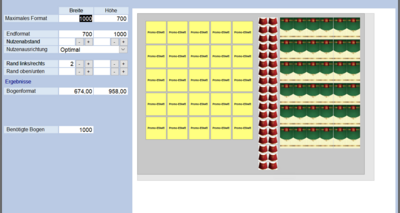

With the Gang Printing optimization C3 allows to create gang printing forms easily and automatically. Complex requests with a lot of variants can be simplified and – as well as single orders – combined. Within the pre-estimation of complex orders e.g. the labels for a bottle – consisting out of front label, back label and bottleneck label – can be put on one sheet. Originating from the target quantity per format, C3 creates possible arrangements and optimizes these concerning the space utilization or needed sheets. During the production different single orders can be collected with different criteria such as colorfulness, finishing or material.

Examining complex rules and plausibility during an estimation are simplified by decision tables. E.g. a decision table "Make Ready + Run Rotogravure”, has any amount of determining criteria and results. An example of determinating criteria would be front colors, back colors and whther to use varnish. Resulting values could be the make ready time and the press speed for each combination of criteria. Decision tables you create ensure that every employee works with the same criteria and receive the same estimated prices for every product.

Additional features at a glance

- Unlimited print runs and production versions (e.g. conventional to digital)

can be calculated simultaneously - Preliminary and final costing as well as current costing

- Partial costs, full costs or activity-based costing

- Offers generated with one click based on item and costing estimations

- Supports all production methods

- Fully flexible and configurable

- Surcharge rates and commission can be individually specified per print run

- Sliding scale prices for materials and items

- Different product variations can be easily generated

- Graphical sheet and cutting optimization

- Optimization of the production variant depending on quantity