DMI | Direct Machine Interface

Industrial monitoring with electronic meters

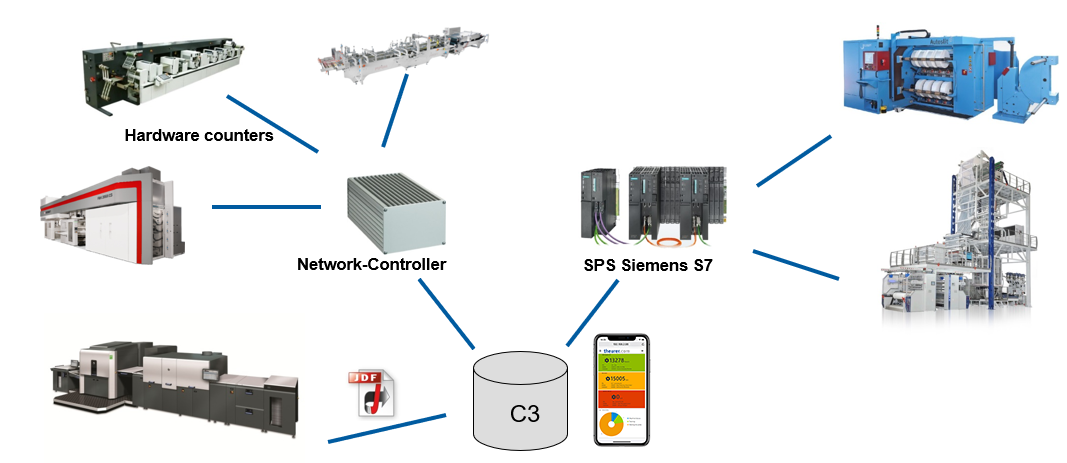

Internet of Things (IOT) in your company: Complementary to the C3 Shop Floor Control Terminals, the direct machines interface via electronic meters also facilitates the automatic collection of machine data using electronic machine meters. Requiring no additional acquisition work, the set-up provides live production data with a tool controlled by a photoelectric sensor. This means that the production is completely recorded and monitored in real time for all connected machines and includes quantities, speeds as well as – as far as technically feasible – finished quantities, waste quantities or overall production quantities and quantities of semi-finished goods.

Your key advantages

- Reliable production data by connecting the management workflow with actual production

- Accurate counting, which eliminates over or under production

- Configurable monitoring board for live data: instantly see who is currently producing which order and at what output

- Tried and tested complete solution with sensors, network controller and software

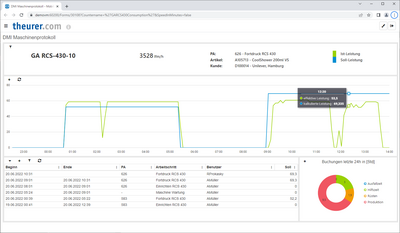

DMI-Monitoring Board

Connecting machines with electronic meters helps ensure precise tracking of material consumption and finished quantities, as well as downtimes and machine status. In practice, this means that the consumption of roll material or details of the finished quantities attained by the folder-gluer machine can be accurately determined. The order progress and machine speed are shown live on the monitoring board allowing e.g. production planners to track production in real time, while the software allows improved production data analysis. The machine connection with electronic meters can be completely integrated into the C3 Shop Floor terminal, while C3 automatically shows when the target quantity has been reached for the current operation.

Machine protocol per shift

The data generated are used for live production tracking and to improve the analysis of production data together with the Business Intelligence & Controlling module. Combining this with Shop Floor data logging allows us to achieve maximum transparency and continuous monitoring of your productive capacity. The data is collected using either additional electronic meters, interfaces to internal meters of the machine manufacturer or a JDF/JMF integration. Various sophisticated sensors are available depending on the counting requirement, while the technical process employed dictates whether an electronic impulse counter, photoelectric sensor or optical meter is used as the basic hardware. The DMI network controller functions as a bridge between the sensor and IT network, whereby the base number data are processed in the DMI network controller and transferred in real time to C3.