JDF | Workflow-Automation

Internal linking of different systems and machines through JDF/JMF can tap into major productivity potential in many areas. C3 can generate various JDF job tickets to this end - depending on use - and process feedback from JMF messages. A true JDF management system, C3 organizes your entire JDF workflow, so it can generate machine-specific JDF job tickets depending on other connected JDF systems on an event-driven basis, for example. The tremendous flexibility of the C3 JDF components also makes it easy to handle manufacturer-specific JDF expansions.

We have been working with many industry partners for years on automation through JDF/JMF integration of theurer.com C3 with prepress workflows, conventional and digital printing equipment and further processing systems. For an idea of what we can do, we present two examples involving our partners Esko and HP Indigo.

Your key advantages at a glance

- Save time and money: Data entry in Esko is reduced to an absolute minimum, as data from the leading C3 system is transferred directly to Esko. Products, customer data and job-orders do not need to be re-entered and data is automatically transferred to the related fields.

- Shorter cycles: Events which initiate tasks for Esko users are promptly transferred and processed in Esko. Approval PDFs, for instance, are available immediately in C3.

- Error reduction: Redundant data entry and manual data transfer of information is permanently avoided and data entry errors are prevented.

The JDF press order is initiated in C3 using C3 master data, i.e. articles, variants and customers to create the corresponding Esko master data. In the process, C3 transfers product specific data such as article number, dimensions, characteristics, in addition to customer PDF files and customer master data. The JDF service order automates the “1-up workflow” which consists of processes ranging from entering master data, PDF delivery and preparation, as well as proofing and changing existing articles. Using Esko Automation Engine, approval information and automatically created JPG and PDF approval files are transferred to C3 and linked with the C3 data. C3 links the original Esko pre-press files instead of creating copies. As a result C3 and Esko are sharing pre-press files.

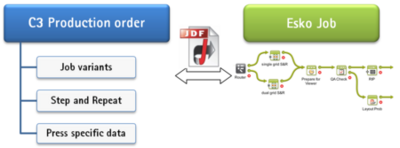

The JDF production order creates “ready to go” jobs in the Esko Automation Engine from C3 production orders. The JDF production order can automate the output production tasks in pre-press including layout, RIP, CTP, etc. In the same way that C3 links article variants into a production order, the JDF will now create a production job in Esko and automatically link in the involved product items. No pre-press operator needs to search or copy files. Depending in the complexity of the layout, this production workflow can also be fully automated – with the possibility of a human checkpoint for a final quality check.

As a result, the JDF production order transfers the necessary data for a specific customer order and manufacturing variant. This could be step and repeat information, gaps, delivery dates, customer order number or data, as well as other Esko SmartNames. Esko Milestones are automatically communicated back to C3. Automated and digital info of the pre-press and plate status will improve press scheduling.

As a part of the HP SmartStream Solution Partner Programm wurde die The JDF/JMF Integration of theurer.com C3 and the HP Indigo Digital Front End (DFE) and the HP SmartStream Labels and Packaging Print Server was developed with in the HP SmartStream Solution Partner Programm. As a result, jobs can be automatically submitted from theurer.com to the DFE, and are available and ready for printing. C3 sends production orders via JDF/JMF with one or multiple stock keeping units (SKUs), directly to the DFE. From C3, production parameters such as color strategy, ink set, PDF file, HP Indigo substrate or finishing marks are defined. For the ripping of data, C3 defines the layout of items on the basis of an existing or planned die cut including gaps and margins and uses the maximum repeat length of HP Indigo WS6600 Digital Press to optimize click costs. As a result, manual post-processing of the jobs on the DFE is not necessary, helping customers to be more efficient and to reduce administrative costs for HP Indigo jobs.

In conjunction with the C3 web portal, the internal organizational effort for order processing, technical order preparation and prepress can be reduced to a minimum. Customers can provide their end customers the option of creating new versions (SKUs) themselves and uploading PDFs directly in their web portal. theurer.com C3 saves complete definitions of HP Indigo jobs including all necessary production parameters for an entire multiple-version (SKU) project. New versions (SKUs) automatically inherit the master data, C3 completes the new jobs and sends them directly to the HP Indigo DFE so customers benefit from an increased process security.